Q&A regarding the Silicone Elastomers World Summit 2020

The CHT Group’s Dr. Petr Schurek recently presented on 3D printable silicones and latest developments in additive manufacturing during the 2020 Silicone Elastomers World Summit. The event took place as an online event on the 15-16th of December. During day two, Dr. Petr Schurek, R&D LSR & 3D Printing at CHT Germany GmbH, shared the latest technological developments for 3D printing.

Our team recently asked Dr. Schurek to share a brief overview on silicones for 3D printing:

Which new possibilities open 3D printing to processing of silicones?

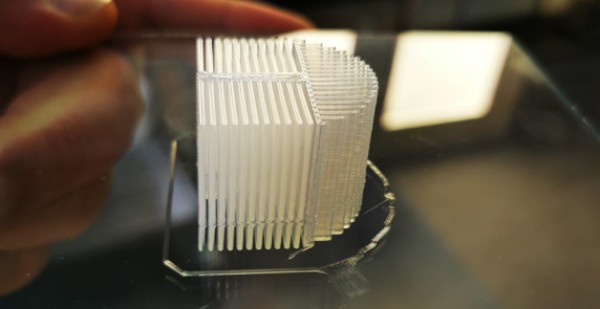

Dr. Schurek: Most existing 3D printers allow only thermoset polymers printing. Although a different printing system is required, 3D printable silicones allow: the quick cycle of prototype iterations (6-20 hours), the production of single or small series parts and the production of parts that cannot be injection molded – if printed objects need to have certain physical properties of silicones.

What are some of the main challenges faced among the 3D printing industry?

Dr. Schurek: The 3D printing industry is relatively new, so not all people are aware of its possibilities and not many have or can operate 3D printers yet. The challenge is to quickly and cost effectively produce silicone parts with a quality close to injection molded parts.

Are there other materials available in the market and how do they compare to 3D printable silicones? What are some key advantages one would find using silicones?

Dr. Schurek: Other materials do not feature soft silicone like properties. Some polyurethanes do but are not biocompatible. A key advantage is: you can print soft rubbery objects with mechanical properties of silicone such as biocompatible, high tear, high tensile strength and elasticity with very complex structures.

Are you able to customize physical properties of silicones to help customers improve their specific processes?

Dr. Schurek: Yes, we can customize formulations. For example, laser writable materials, self-adhesive, electrically conductive, electrically insulating, and biocompatibility.

What are the differences in the mechanical properties between an injection moulded silicone part versus a 3D printed silicone part?

Dr. Schurek: We are close to 100 % with the current development.

What are the most likely applications for CHT’s 3D materials?

Dr. Schurek: Basically, any industry can benefit from 3D printing, especially when it comes to spare parts and tailor-made parts, such as in the orthopaedic sector. The volume productions are small.

What are the optical applications targeted?

Dr. Schurek: We currently have a project with a translucent sealing for a lighting customer.

You mentioned that CHT also offers optical silicone materials and MQ resin products. Are these products LSR for LIM processing or optical encapsulants for casting/potting processing?

Dr. Schurek: We offer both chemistries.

What is the dimensional accuracy of the part after curing?

Dr. Schurek: Identical to standard LSR parts after Injection Moulding, the substance loss is less than one percent.

More about the event:

The Elastomers World Summit Online brings together manufacturers, processors, end-users, designers and researchers for a summit-style technical discussion of silicone elastomer materials, their global market trends, processing advancements and novel applications.

To learn more about the summit, please visit: https://www.elastomer-forum.com/home

About the presenter:

Dr. Petr Schurek is currently the head researcher at CHT Tübingen and is responsible for various strategic projects including 3D printing with silicones.

Dr. Petr Schurek is currently the head researcher at CHT Tübingen and is responsible for various strategic projects including 3D printing with silicones.

Dr. Schurek holds an RNDr. from the University Palacky Olomouc in Biophysics and Physical chemistry and Nuclear Physics from VSCHT. Previously, Dr. Schurek has worked at chemical companies in Czech, Spain, South Africa, USA and Germany in various technical and managerial positions.

Please contact our Material Solutions Team to discuss how we can help you using our contact form